A flexible splinting platform that provides high quality immobilization in the field.

The Problem.

Currently, there is a need for an intuitive, easily sanitizable, and adjustable splinting device that can be deployed by EMS or SOF medics in remote or austere environments to treat an unknown injury.

In emergency rescue situations, medics are often forced to improvise for a variety of extremity related injuries, leading to further structural damage within the body, as well as discomfort to the patient.

Background

A small team of students including myself worked with a startup to re-imagine and re-engineer a product they are developing known as the RES or rescue extremity splint. This project culminated in a completely redesigned prototype as well as a series of recommendations and decision points for various materials and manufacturing techniques. These recommendations were then contextualized by price point and target user.

Constraints

The design of the new and improved prototype focussed on everything from manufacturability to radiolucency (to aid in imaging in triage scenarios). The objective was to create a modular and adaptable splinting platform that could be employed in austere environments. Designing for all of these characteristics while still hitting a price point and minimizing complexity of manufacturing and assembly was a constant focus.

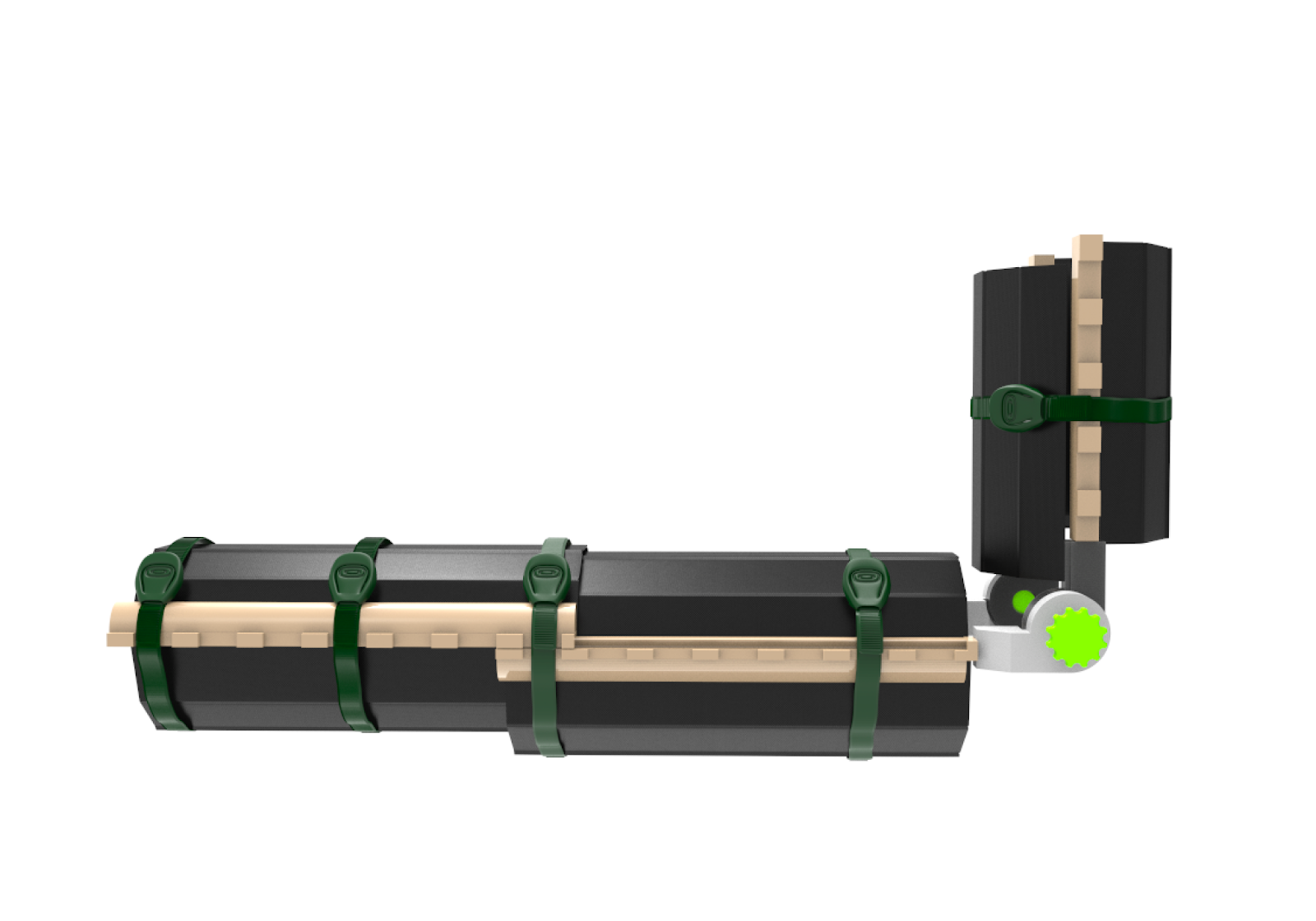

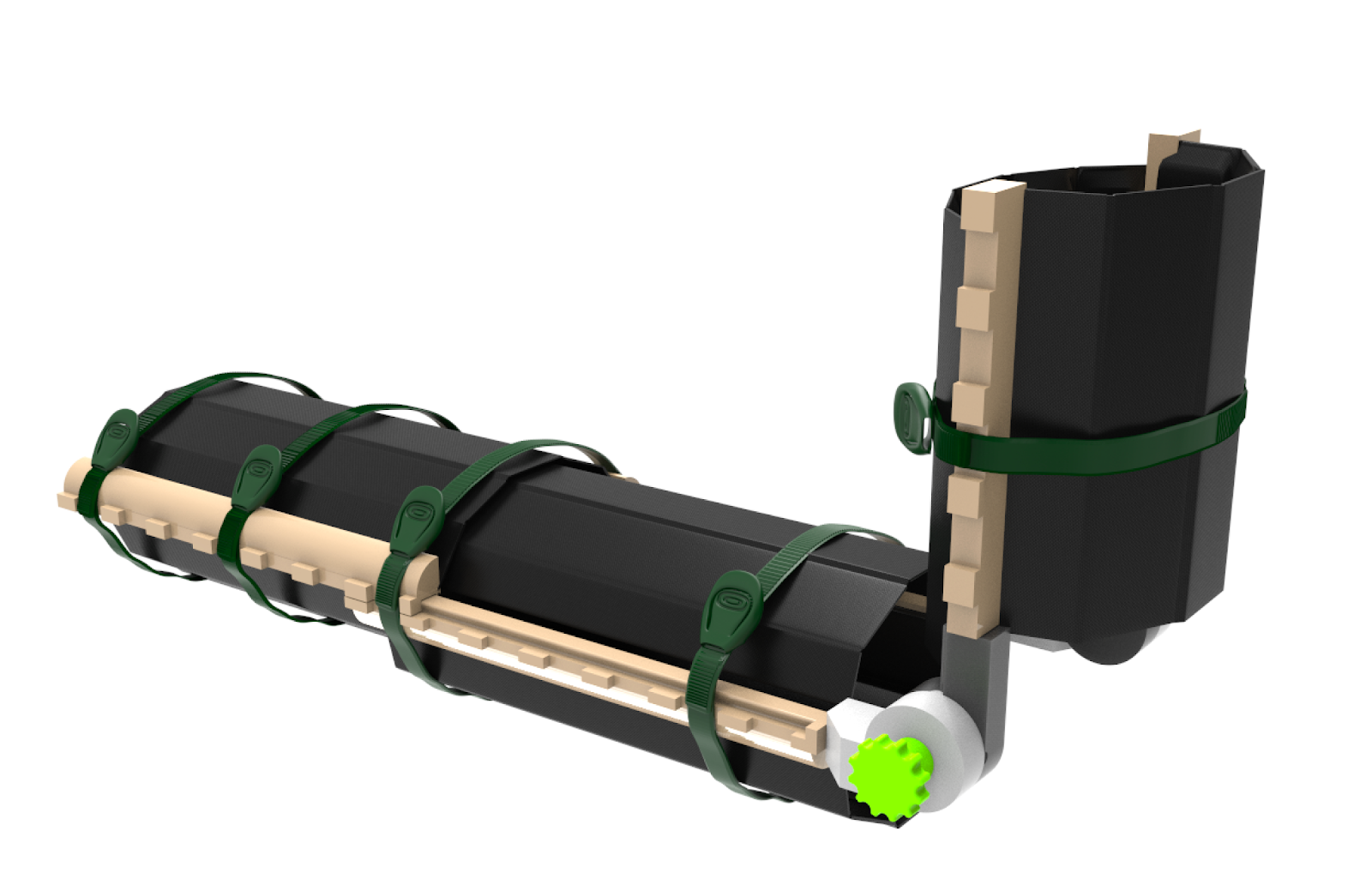

All the use configuration in a color coded format.

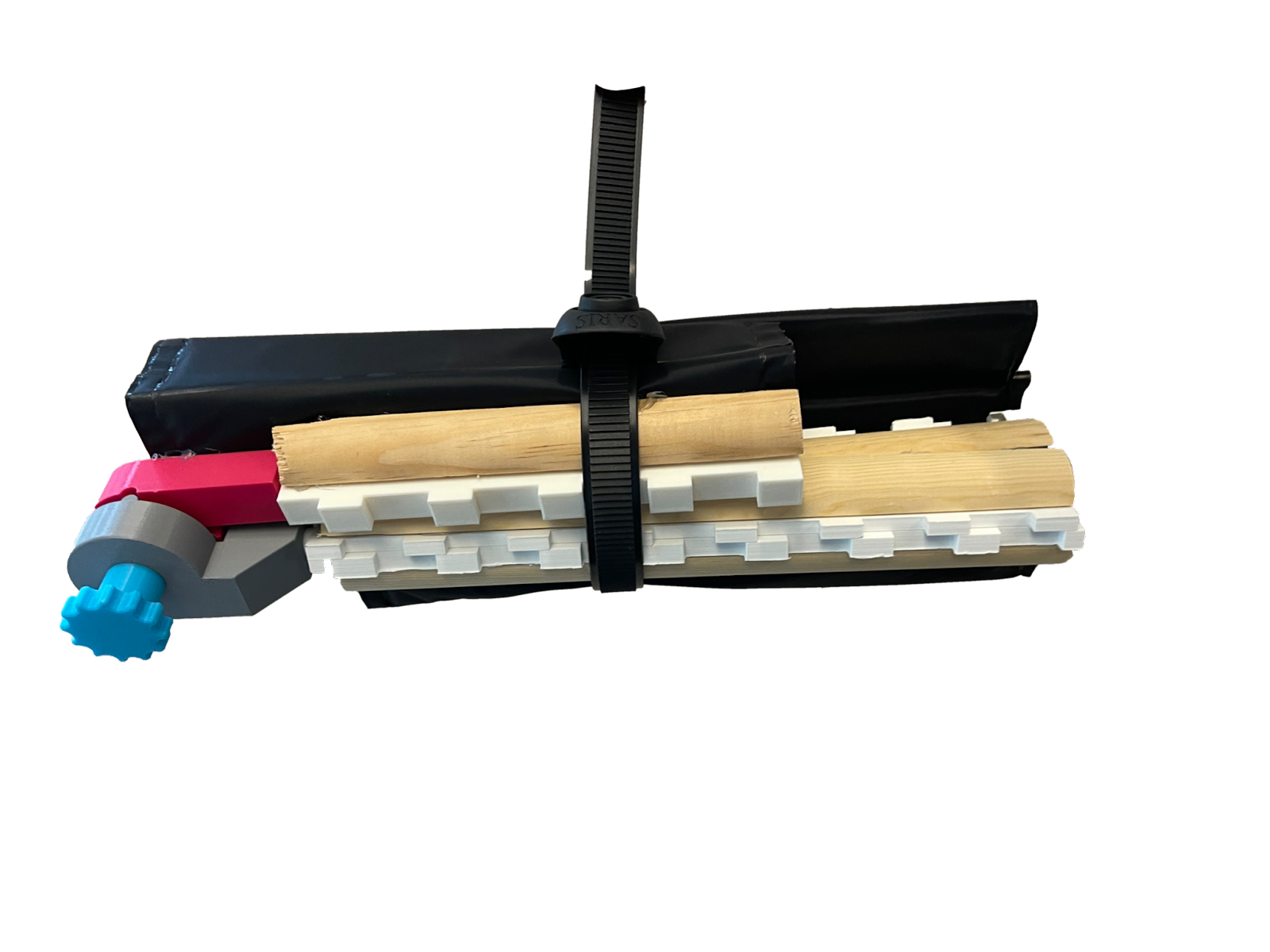

Prototype hinges, rails, pads, and complete splints from beginning (left) to final (right) iterations.